ΑΠΟΣΤΟΛΗ ΚΑΙ ΣΤΟΧΟΣ

" Η συνεχής Υποστήριξη του Επιχειρηματικού Κόσμου! "

H COSMOS ΣΥΜΒΟΥΛΕΥΤΙΚΗ A.E. είναι μία από τις πιο ανταγωνιστικές Εταιρείες Συμβούλων Συμβούλων Επιχειρήσεων στην Ελλάδα, η οποία έχει παρουσία στον επιχειρηματικό στίβο περισσότερο από μια δεκαετία και αποτελεί μία ευέλικτη και δυναμική επιχείρηση με ραγδαίους ρυθμούς ανάπτυξης και προηγμένη τεχνογνωσία σε όλους τους τομείς. Δραστηριοποιείται στον τομέα της παροχής συμβουλευτικών υπηρεσιών προς επιχειρήσεις και οργανισμούς Ιδιωτικού & Δημοσίου Τομέα, παρέχοντας μια ευρεία γκάμα υπηρεσιών για την ανάπτυξη, την οργάνωση και τον εκσυγχρονισμό των επιχειρήσεων. Η φιλοσοφία της εταιρίας βασίζεται στις βασικές αρχές της Ποιότητας των Υπηρεσιών, Συνέπειας, Αποτελεσματικότητας και Αφοσίωσης προς όλους τους πελάτες της.

Υπηρεσίες

Έργα επενδύσεων

Στα πλαίσια των Ευρωπαϊκών & Διεθνών Ενισχύσεων, στην εταιρεία λειτουργεί εξειδικευμένο τμήμα, το οποίο παρακολουθεί την εξέλιξη αυτών και τις ευκαιρίες επιδότησης επιχειρήσεων και Οργανισμών του Δημοσίου μέσω υλοποίησης επενδυτικών σχεδίων.

Έργα διαχείρισης ποιότητας

Στην COSMOS ΣΥΜΒΟΥΛΕΥΤΙΚΗ Α.Ε. λειτουργεί εξειδικευμένο τμήμα, μέσω του οποίου αναλαμβάνουμε την υποστήριξη επιχειρήσεων είτε μέσω μακροχρόνιας συνεργασίας (consulting) είτε μέσω συγκεκριμένων έργων – μελετών.

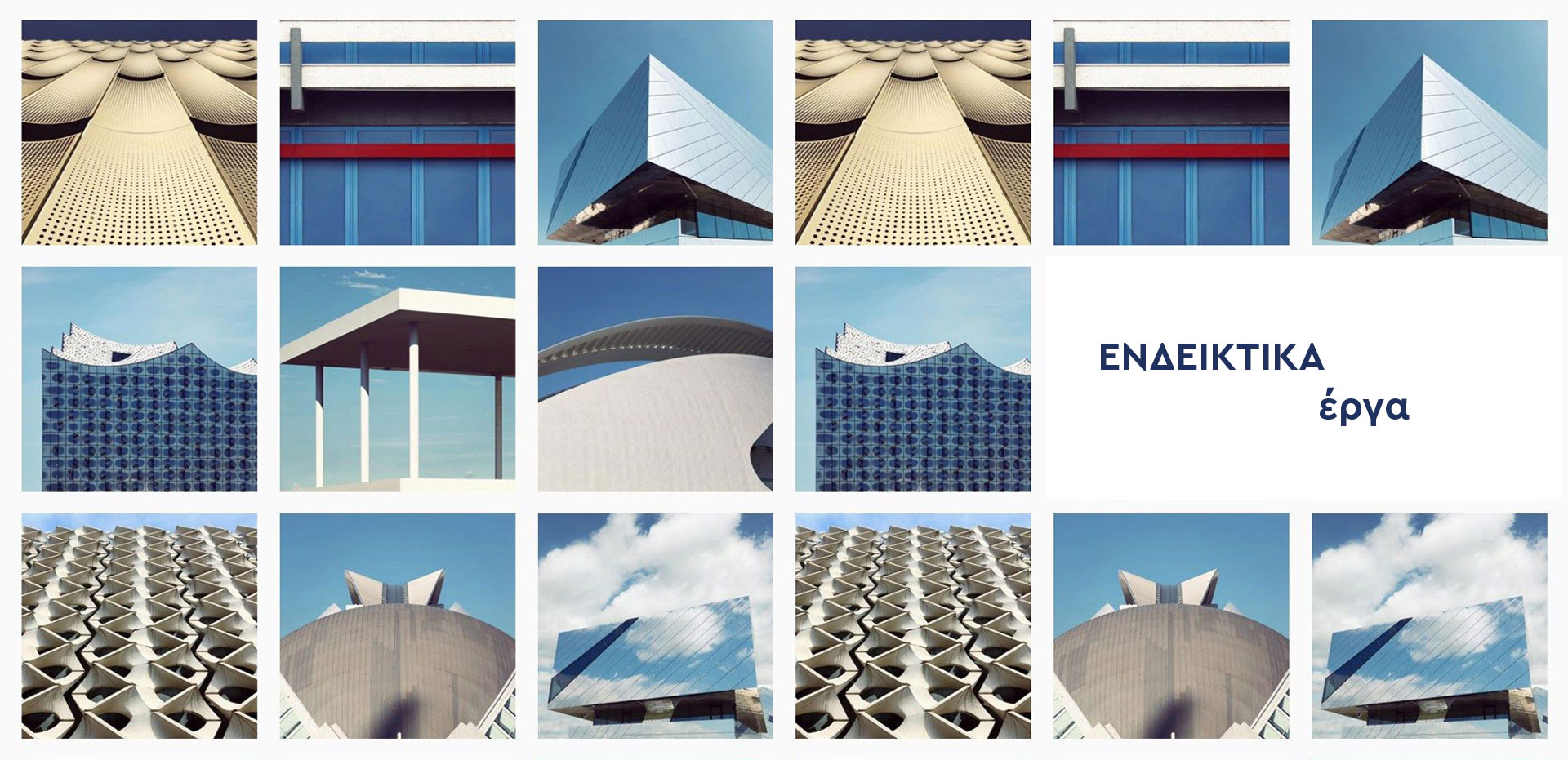

Πελάτες

ΣΥΜΒΟΥΛΟΙ ΕΠΕΝΔΥΣΕΩΝ

Περισσότεροι από 1000 πελάτες εμπιστεύονται την COSMOS Συμβουλευτική. Κάποιοι από αυτούς ανά τομέα είναι:

ΣΥΜΒΟΥΛΟΙ ΣΥΣΤΗΜΑΤΩΝ ΔΙΑΧΕΙΡΙΣΗΣ ΠΟΙΟΤΗΤΑΣ

Περισσότεροι από 1000 πελάτες εμπιστεύονται την COSMOS Συμβουλευτική. Κάποιοι από αυτούς ανά τομέα είναι: